BUSINESS

We will make efforts to improve systematic quality management and service.

Technology

- Optoform 80

- aspherical design

- plasma

- C.I.P. method

- UV protection effect

- Packaging machine/cleaning/automatic hydration

- Precision Optical Processing Machine Optoform 80

- When working with RGP lens or soft lens mold core, 1/10th of the precision production is possible.

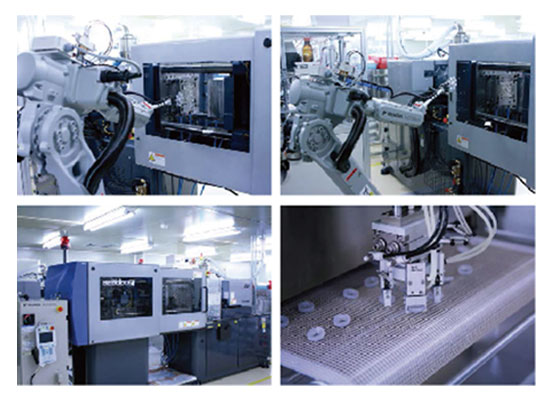

- Cast Molding Process

- DKMedivision's cast molding system is a technology suitable for the production of contact lenses that require precision, and is produced non-stop through an automated line from mold production to contact lens production.

- Cast molding technology combines an upper mold and a lower mold, so there is almost no error in product manufacturing, and the surface is made evenly, so it boasts excellent wearability and optical performance.

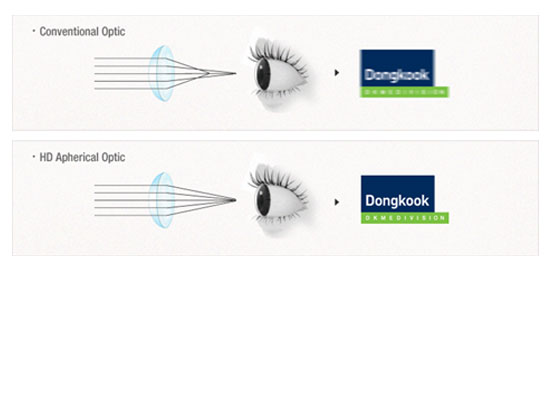

- High resolution aspherical design

- The aspherical design reduces distortion and spherical aberration, providing a clear view during the day as well as at night.

- Surface plasma treatment

- The wetting angle of the lens surface is lowered, which helps to improve dryness and improve the deposition of foreign substances.

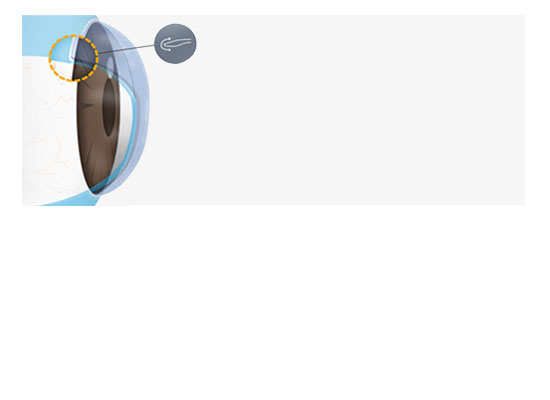

- Precision Edge Design

- The sophisticated edge design that hardly irritates the cornea improves the feeling of dryness and wearing comfort by facilitating tear circulation and excretion of foreign substances.

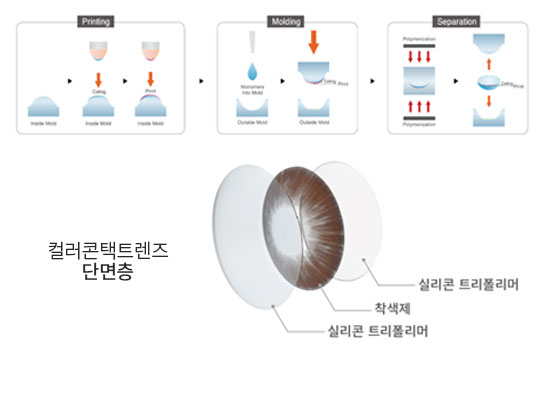

- Cast Molding + C.I.P. Process

- It is a method of inserting a collar between the lens layers while maintaining the thin and light half-lens.

- We use materials that have been proven safe by the US FDA.

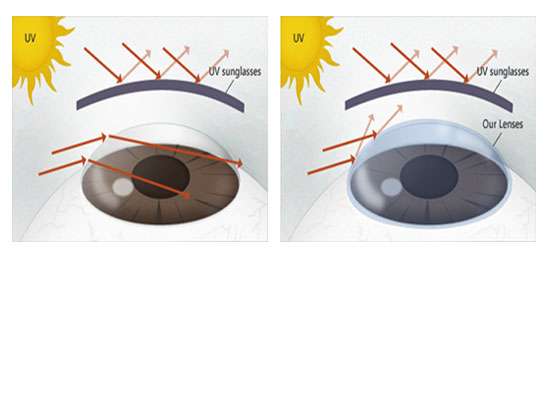

- UV Blocking

- UV-blocking contact lenses protect the cornea from harmful UV rays from UV rays A and B, which can cause eye diseases such as cataracts or retinal damage due to prolonged UV exposure.

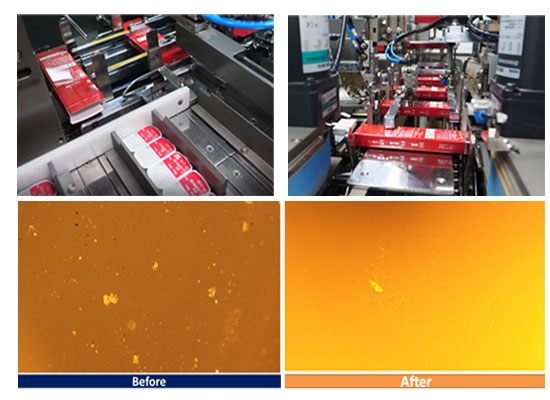

- automated packaging machine

- Introduction of automatic primary & secondary packaging machines has been completed.

- It keeps the cleanliness until the final process as it is not directly touched by the operator until the final pack case packaging.

- Ultrasonic Cleaning & Auto Hydration Process

- Clean surface condition is realized by introducing ultrasonic cleaning process.

- Use of automated equipment.